Control valves are the unsung heroes of industrial processes, silently regulating flows in harsh environments. Yet, 43% of premature valve failures stem from preventable issues like improper maintenance or cavitation (2023 Valve Industry Report). By implementing these 7 data-backed strategies – including specialized fluorine-lined valve applications – you can boost valve service life by 50% or more while cutting replacement costs.

1. Precision Maintenance: Beyond Basic Checks

Why it matters: A study by the Fluid Controls Institute found valves with scheduled maintenance last 2.3x longer.

Actionable Protocol:

For fluorine-lined valves: Conduct quarterly PTFE liner thickness checks via ultrasonic testing

Use compatible lubricants (silicone-based for fluoropolymer components)

Special attention to bolt torque (PTFE gaskets require retorquing after 48hrs of service)

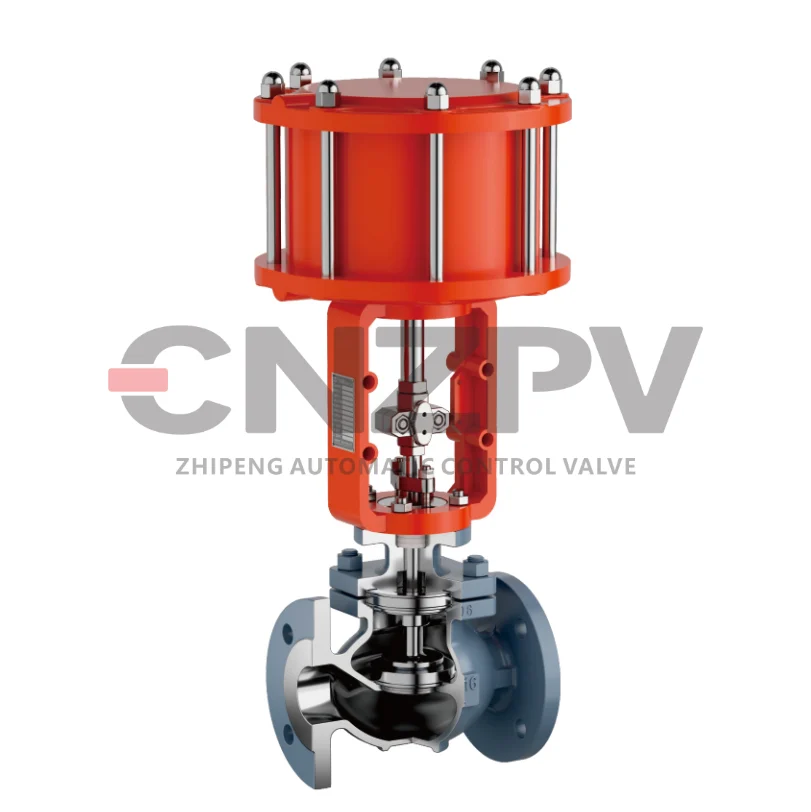

2. Fluorine-Lined Valves: The Corrosion Solution

Game-Changing Advantage: Fluoropolymer-lined valves demonstrate 97% survival rate after 5 years in sulfuric acid service (Garlock Case Study).

Key Benefits:

✔ Chemical Immunity: Withstands pH 0-14, including aqua regia and chlorine gas

✔ Temperature Range: -200°C to +180°C with PFA liners

✔ Cost Efficiency: 60% lighter than solid alloy valves, reducing actuator load

✔ Non-Stick Surface: Prevents scaling and particulate buildup

Liner Material Comparison:

| Material | Max Temp | Best For | Service Life |

| PTFE | 150°C | General acids | 5-7 years |

| PFA | 180°C | Ultra-pure processes | 8-10 years |

| ETFE | 150°C | Oxidizing agents | 6-8 years |

3. Combatting the Silent Killers: Cavitation & Flashing

The Cost: Unchecked cavitation can erode valve trim 10x faster than normal wear.

Fluorine-Lined Valve Solutions:

Lined valves inherently resist cavitation damage due to elastomeric backing

PFA-lined trims maintain smooth surface finish (Ra <0.8μm) to prevent nucleation

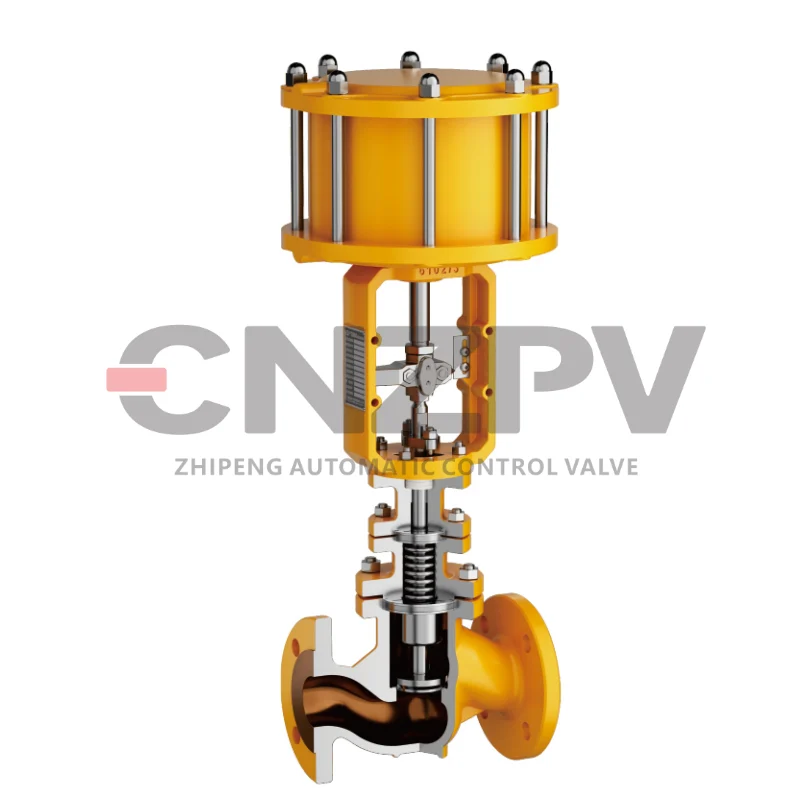

4. Material Science Approach

Breakthrough: Vortex-shedding resistant alloys like Duplex 2205 extend trim life by 40% in slurry services.

Fluorine-Lined Valve Enhancement:

Hybrid designs with alloy bodies + fluoropolymer liners combine structural strength with chemical resistance

Electropolished metallic components prevent liner abrasion

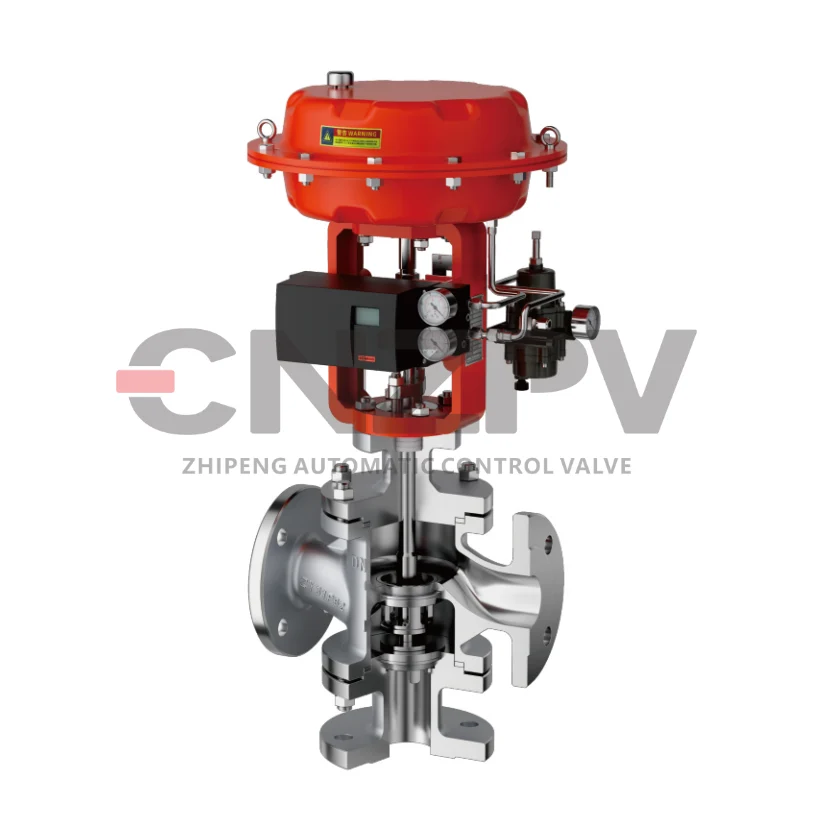

5. Smart Valve Analytics

IoT Advantage: Plants with IIoT-enabled valves report 72% fewer unplanned shutdowns (ABB Whitepaper).

Fluorine-Lined Valve Monitoring:

– Dielectric sensors detect liner degradation before leaks occur

– Temperature mapping ensures liner stays within Tg (glass transition) limits

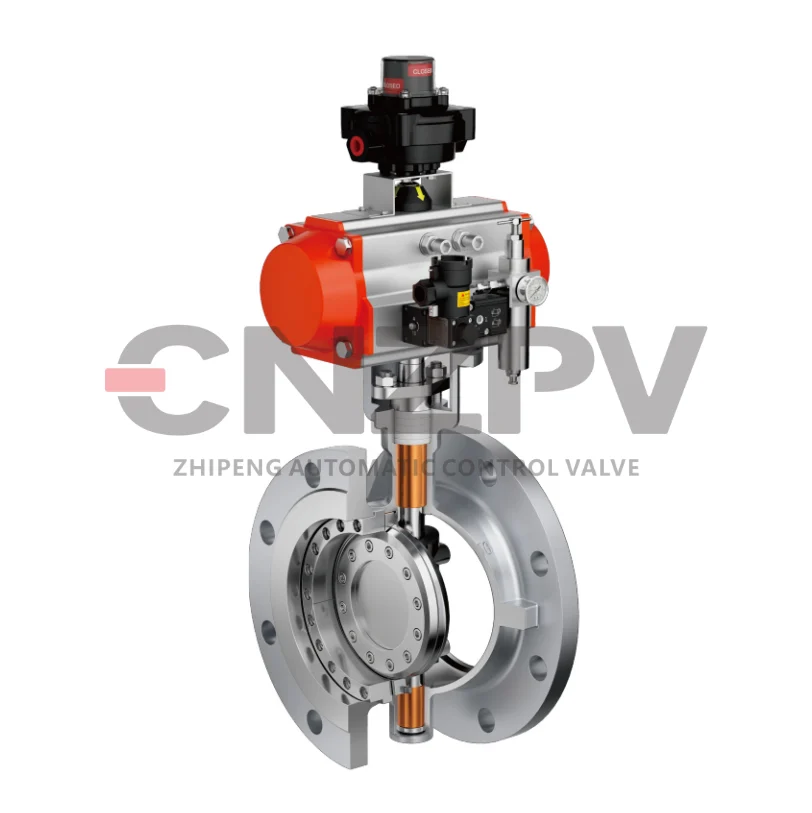

6. Installation Mastery

Critical Error: 68% of field failures originate from improper installation (Emerson Case Study).

Fluorine-Lined Valve Specifics:

✓ Always use flange spreaders – never pry liners during installation

✓ Pre-compress PTFE gaskets at 50°C above operating temp

✓ Avoid sharp bends – maintain 5D radius for lined piping

7. Failure Mode Clinics

Transformative Practice: Tear-down analysis reveals:

Fluorine-Lined Valve Findings:

90% of failures occur at unlined components (stems, bolts)

Properly installed liners typically outlast valve bodies

Most common issue: Thermal cycling beyond liner specs

Your Next Steps

Free Lined Valve Assessment] Our engineers use borescopes and dielectric testing to evaluate liner condition

Download Chemical Resistance Guide] Interactive material selection tool for aggressive media