Control valves play a vital role in industrial fluid systems, enabling accurate flow regulation. A crucial design aspect is the flow direction – high-inlet low-outlet (HILO) or low-inlet high-outlet (LOHI). Picking the appropriate flow direction can enhance valve performance, prolong service life, and avoid operational problems.

Let’s delve into:

- The main differences between HILO and LOHI control valves

- The most suitable applications for each flow direction

- How to pick the right valve for your system

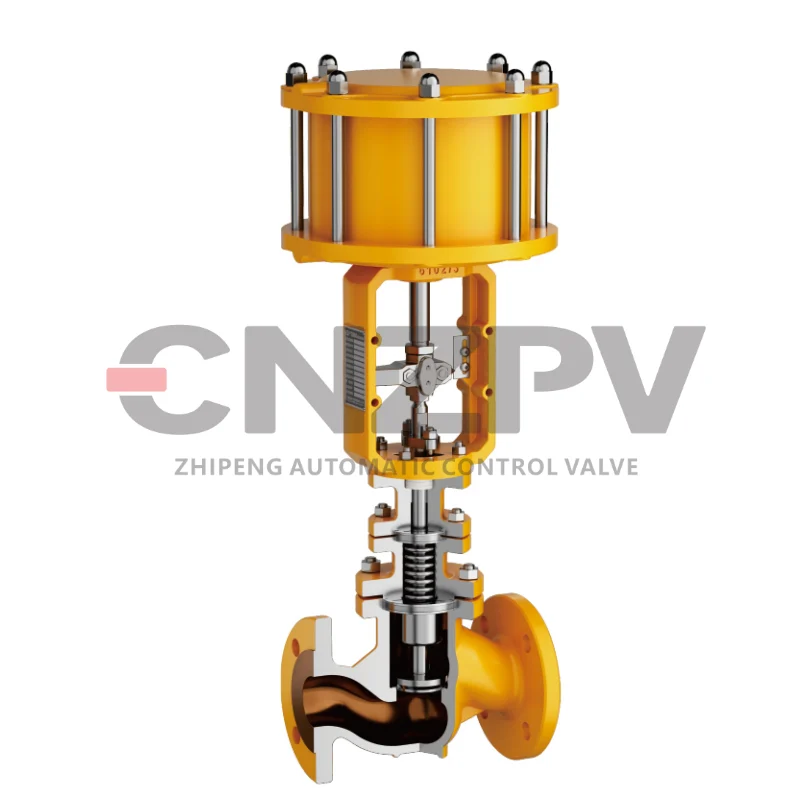

1. High-Inlet Low-Outlet (HILO) Control Valves

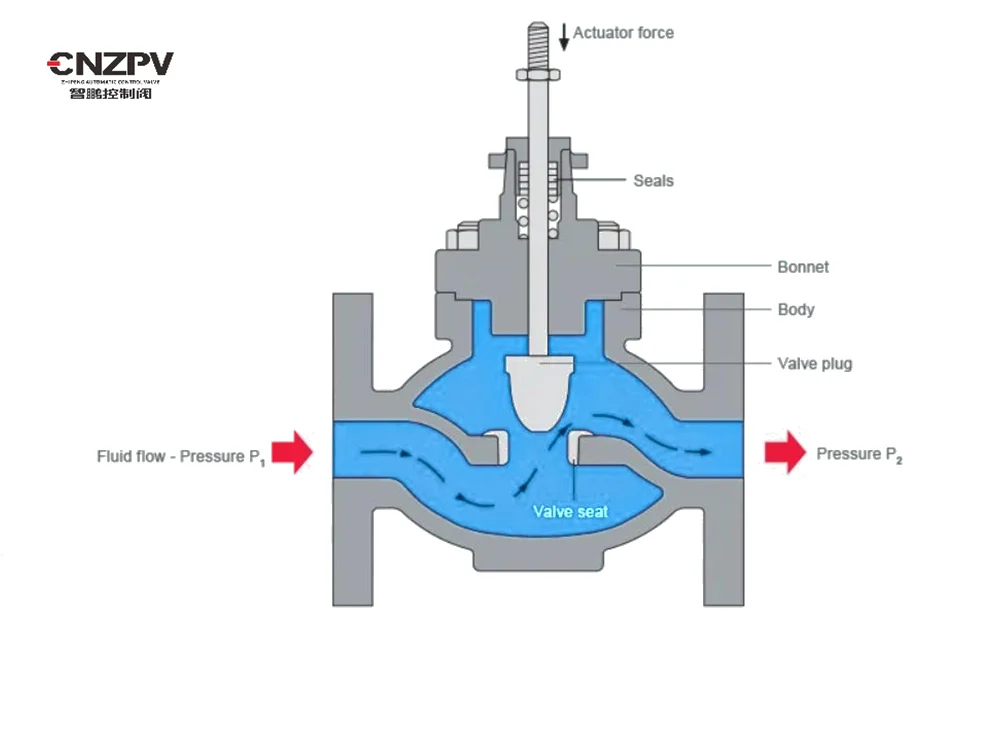

How It Functions

In HILO valves, fluid comes in from the top (high-pressure side) and goes out from the bottom (low-pressure side). This design makes the valve plug move towards the seat, increasing the sealing force. When fluid enters from the high-pressure top, it creates a downward pressure that continuously acts on the valve plug, pushing it tightly against the seat, similar to an invisible hand pressing down, thus significantly boosting the sealing effect.

Advantages

- Superior sealing performance – Perfect for high-pressure shutoff.

- Less actuator force needed – Easier to close when under high pressure.

- Stable control in high-pressure systems – Minimizes vibration and wear.

- Stability in high-temperature environments – The structural design of HILO control valves can reduce sealing failure caused by temperature changes, maintaining stable performance in high-temperature working conditions.

Common Applications

- Steam systems (such as boilers and turbines in large thermal power plants, where HILO control valves can precisely control steam flow to ensure the stable operation of power generation equipment)

- High-pressure gas pipelines

- Systems that require tight shutoff (like chemical processing)

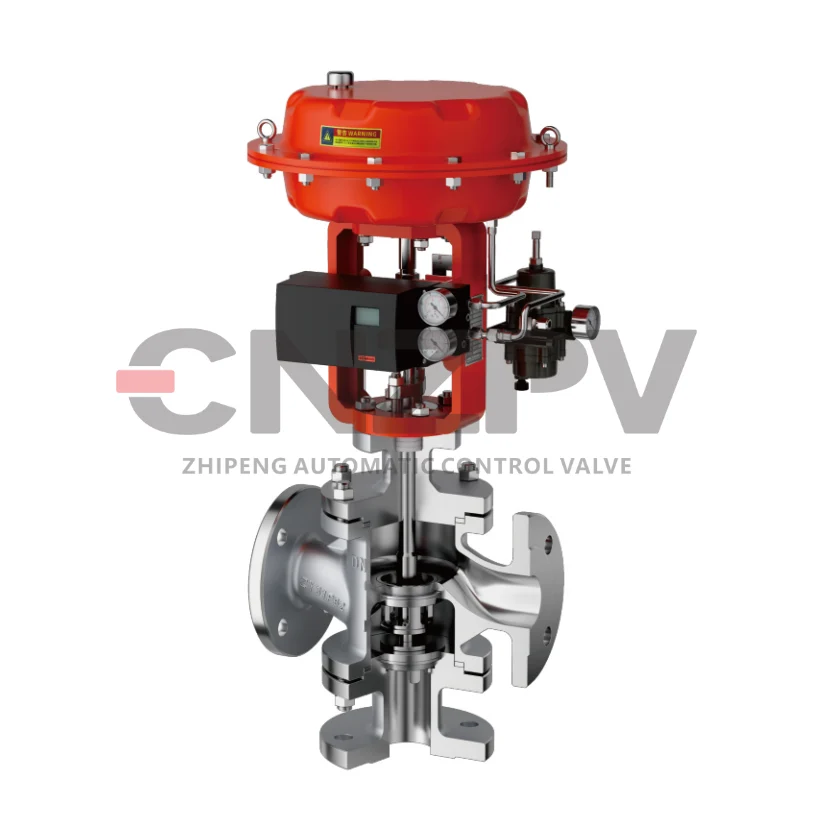

2.Low-Inlet High-Outlet (LOHI) Control Valves

How It Functions

In LOHI valves, fluid enters from the bottom (low-pressure side) and exits from the top (high-pressure side). This design helps lift the plug, reducing the resistance when opening. When fluid enters from the low-pressure bottom, it generates an upward thrust on the valve plug, which acts as an upward spring to assist in opening the valve, making it easier to open and reducing the resistance during the opening process.

Advantages

- Easier to open – Requires less actuator force.

- Reduced clogging – Better for slurries, viscous fluids, or particles. Because fluid enters from the bottom, larger particles and impurities can be smoothly discharged along with the fluid, not easily accumulating near the valve seat, thus effectively reducing the possibility of clogging.

- Improved flow efficiency – Suitable for large-diameter valves.

Common Applications

- Water and wastewater treatment (in the drainage system of sedimentation tanks in urban sewage treatment plants, LOHI control valves can efficiently handle sewage containing a large amount of impurities, ensuring smooth drainage)

- Slurry and abrasive media handling

- Low-pressure liquid control

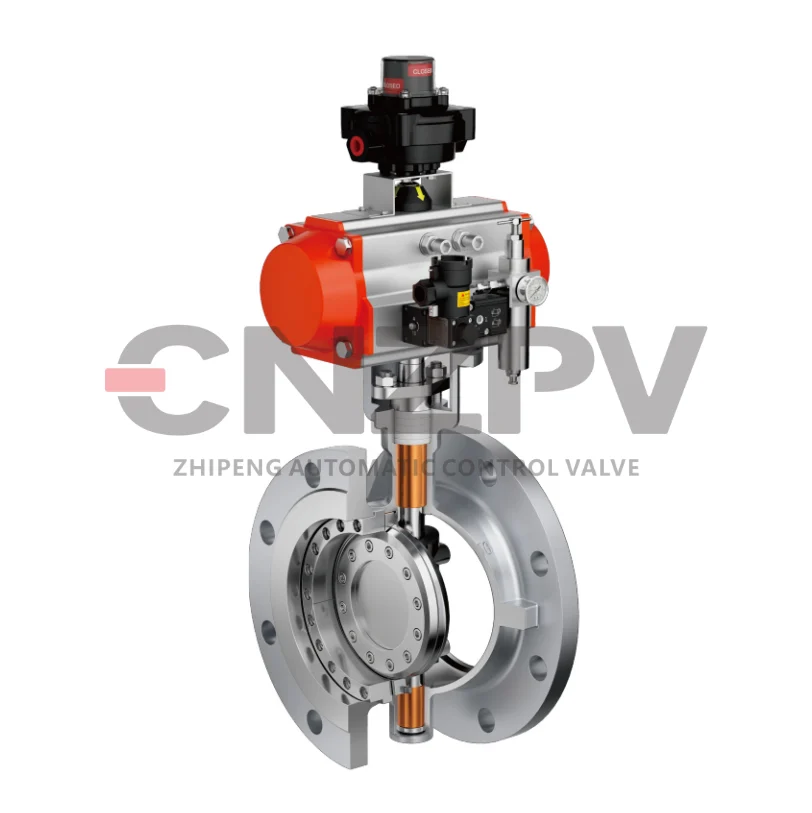

3.Key Selection Factors

When choosing between HILO and LOHI, take into account:

- Pressure conditions – High-pressure systems tend to favor HILO; low-pressure systems may use LOHI.

- Fluid type – Clean fluids work well with HILO, while slurries or viscous liquids require LOHI.

- Sealing requirements – HILO is better for tight shutoff.

- Actuator sizing – LOHI may need more force to close.

- Temperature factors – Different temperature conditions can affect the material performance and sealing effect of control valves. HILO control valves may be more suitable in high-temperature environments, while LOHI control valves may perform better in low-temperature environments.

4.Conclusion: Which One to Choose?

| Feature | HILO (High-Inlet Low-Outlet) | LOHI (Low-Inlet High-Outlet) |

| Sealing | Excellent | Good |

| Actuator Force | Lower closing force | Higher closing force |

| Best For | High-pressure, clean fluids | Slurries, low-pressure systems |

For high-pressure and precise control, choose HILO. For slurries, wastewater, or low-pressure systems, LOHI is more effective.

In actual selection, you can first determine the maximum pressure of the system and the main components of the fluid, then combine the sealing requirements and the capability of the actuator to comprehensively judge whether to choose HILO or LOHI control valves.

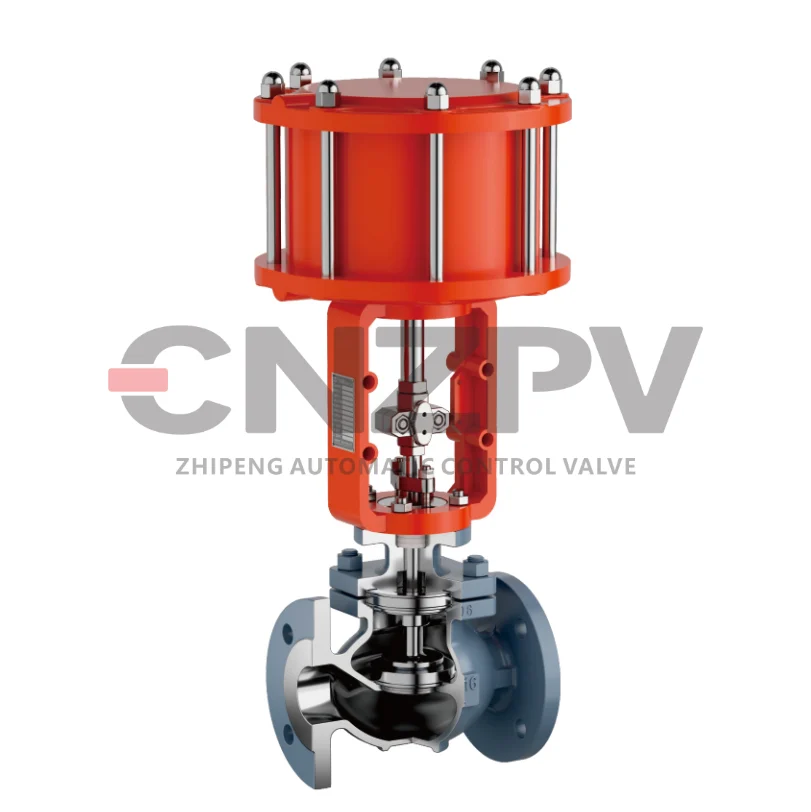

Need Expert Valve Selection?

At Zhipeng Valve, we offer high-quality control valves customized to your industrial needs. Contact us today for a personalized solution!

- Whatsapp us: [+86-158 5802 8828]

- Visit: [www.zpcontrolvalve.com / www.cnzpv.com]

- Email: [[email protected]]