Aug.2025/By CNZPV

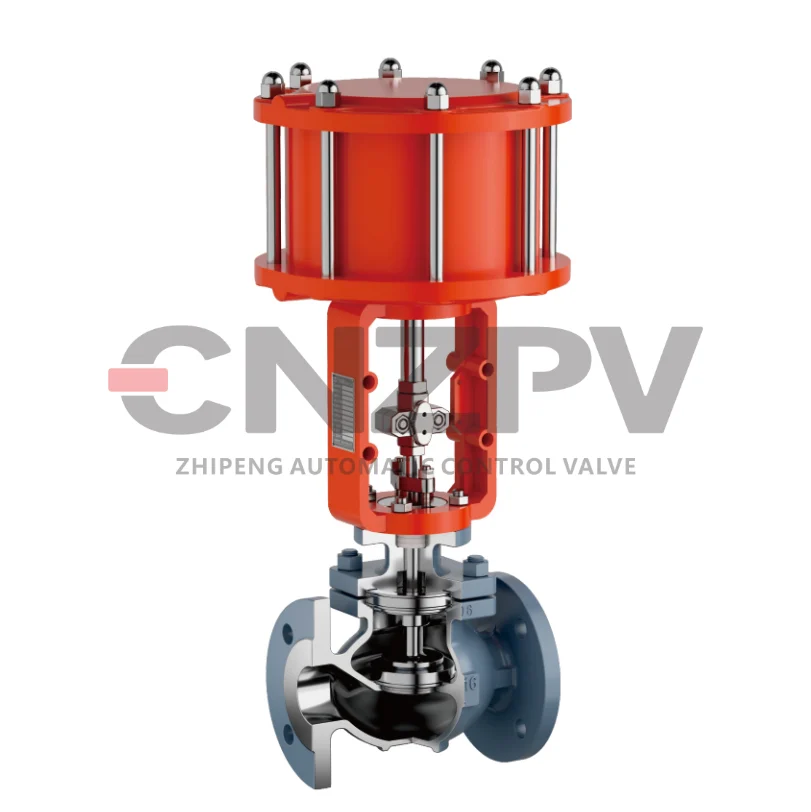

When selecting lined control valves (such as PTFE-lined, PFA-lined, or other fluoropolymer-lined valves) for corrosive or high-purity applications, quality is non-negotiable. Poor-quality valves can lead to leaks, premature failure, and costly downtime.

To help you make an informed decision, here are 7 key quality indicators to evaluate when choosing a lined control valve.

1.Lining Material & Thickness

Why it matters: The lining material (PTFE, PFA,FEP, etc.) determines chemical resistance, while thickness affects durability.

High-quality valves: Use virgin-grade fluoropolymers (not recycled) with uniform thickness (typically 3-5mm).

Low-quality signs: Thin or uneven lining, visible defects, or use of filler materials.

Pro Tip: Ask for material certifications.

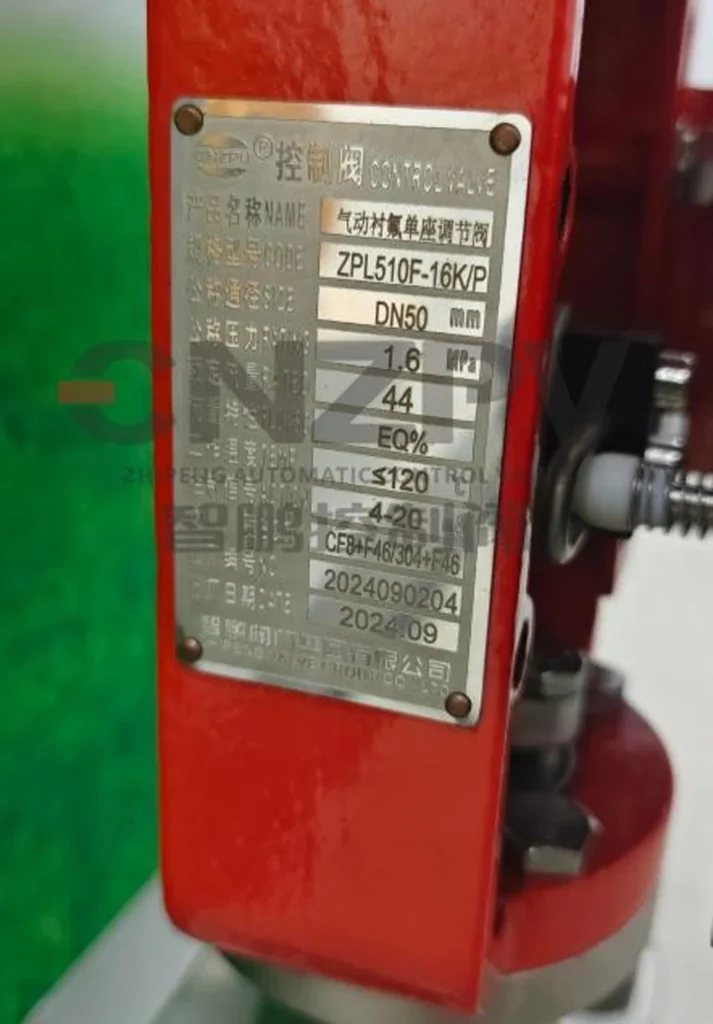

2.Pressure & Temperature Ratings

Why it matters: Lined valves must withstand system pressures and temperatures without deformation.

High-quality valves: Clearly specify maximum working pressure (e.g., 150 PSI, 10 bar) and temperature range (e.g., -20°C to 180°C for PTFE).

Low-quality signs: Vague or exaggerated ratings without test reports.

Pro Tip: Request pressure test certificates (hydrostatic & pneumatic).

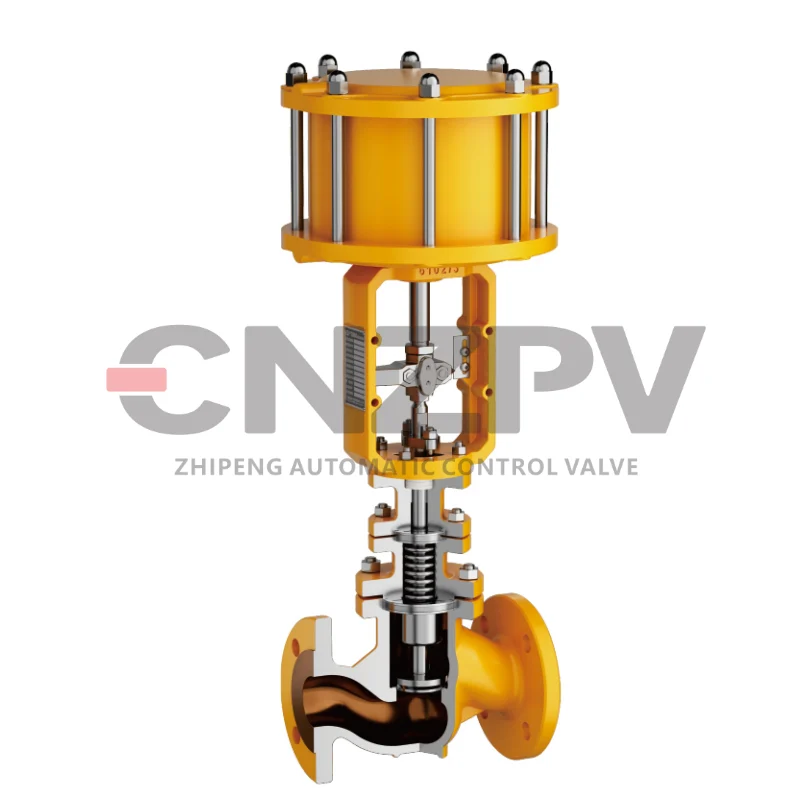

3.Valve Body Construction

Why it matters: The body material (cast iron, carbon steel, stainless steel) affects structural integrity.

High-quality valves: Use ASTM-certified materials with proper corrosion protection (epoxy coating for cast iron).

Low-quality signs: Rough casting marks, weak weld joints, or rust-prone surfaces.

Pro Tip: Check for ISO 9001 or PED compliance for manufacturing standards.

4.Leakage Class (Seat Tightness)

Why it matters: Poor sealing leads to fugitive emissions and process contamination.

High-quality valves: Meet ANSI FCI 70-2 Class IV or Class VI for tight shut-off.

Low-quality signs: High leakage rates in testing or visible gaps in the seat.

Pro Tip: Ask for bubble-tight shut-off guarantees for critical applications.

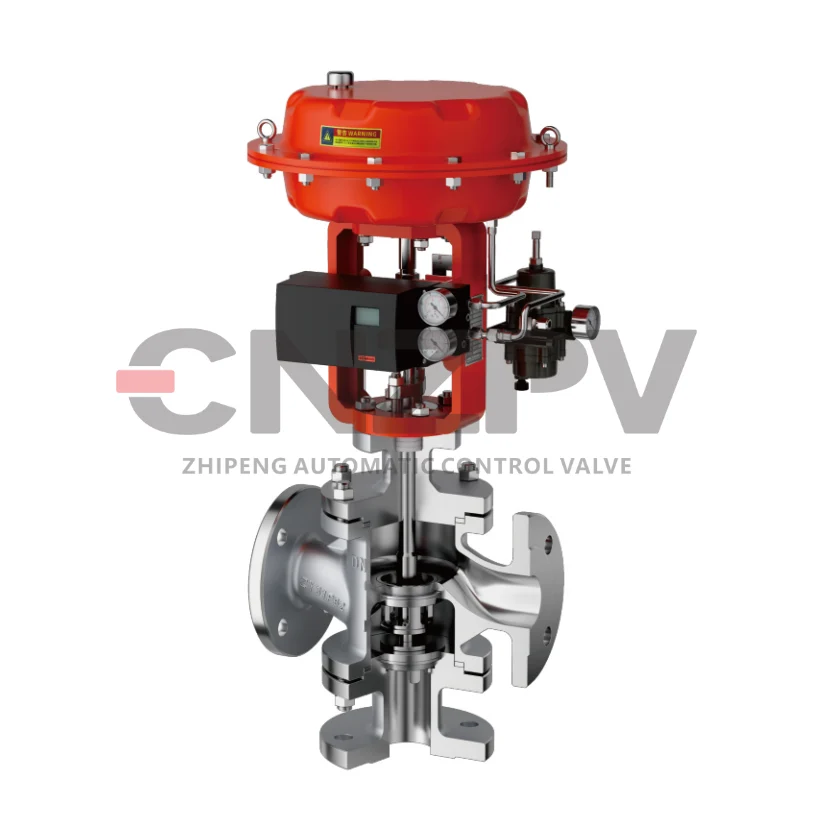

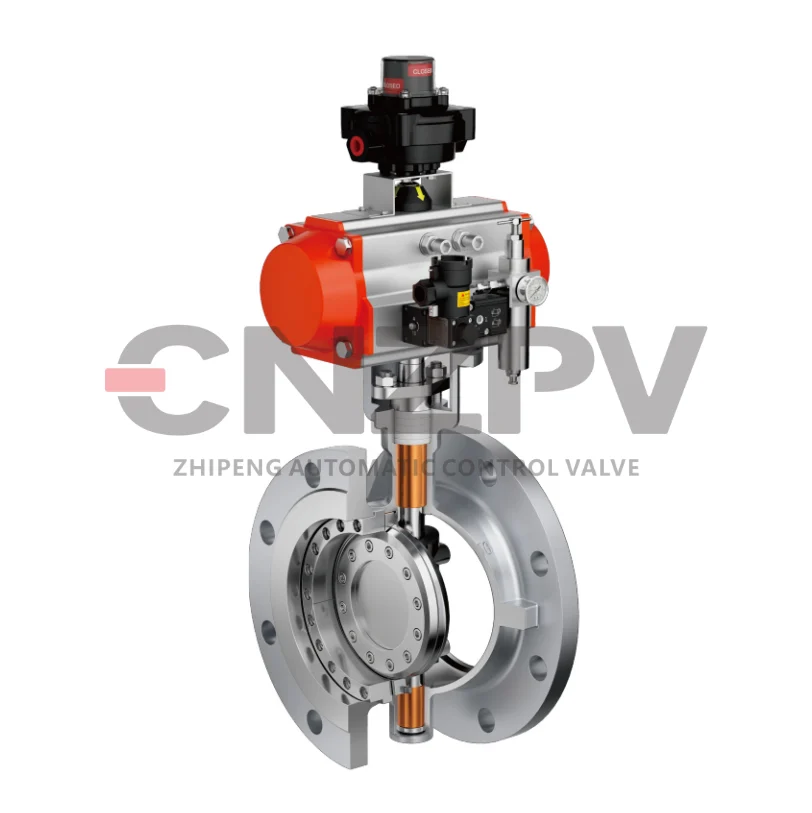

5.Actuator Compatibility & Performance

Why it matters: A poorly matched actuator can cause sluggish response or failure.

High-quality valves: Offer smooth actuation (pneumatic, electric, or hydraulic) with minimal hysteresis.

Low-quality signs: Jerky movement, excessive friction, or misalignment.

Pro Tip: Look for ISO 5211 mounting pads for easy actuator integration.

6.End Connections & Flange Standards

Why it matters: Improper connections cause leaks and safety hazards.

High-quality valves: Comply with ANSI, DIN, or ASME flange standards and provide RF (Raised Face) or RTJ (Ring-Type Joint) options.

Low-quality signs: Mismatched bolt holes, poor surface finish, or non-standard dimensions.

Pro Tip: Verify flange flatness with a straightedge before installation.

7.Manufacturer Reputation & Testing

Why it matters: Reliable suppliers provide consistent quality and support.

High-quality valves: Come with full documentation (material certs, test reports, manuals) and warranty (1-3 years).

Low-quality signs: No traceability, lack of testing data, or unresponsive support.

Pro Tip: Check for third-party certifications (API, TA-Luft, SIL).

Final Checklist Before Purchase

✅ Material Certifications (PTFE/PFA grade, FDA if needed)

✅ Pressure & Temperature Test Reports

✅ Leakage Class Verification

✅ Actuator Compatibility Check

✅ Flange Standards Compliance

✅ Manufacturer’s Warranty & Support

By evaluating these 7 critical quality indicators, you can avoid substandard lined control valves and ensure long-term reliability in harsh chemical or high-purity processes.

Need expert advice? Contact CNZPV for a customized valve selection guide.