Introduction

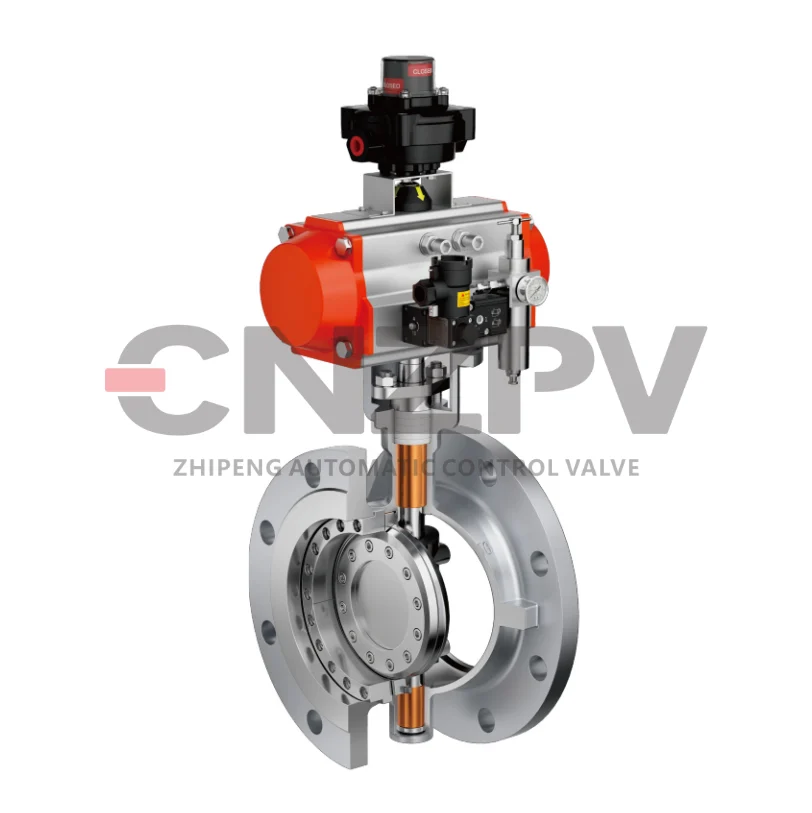

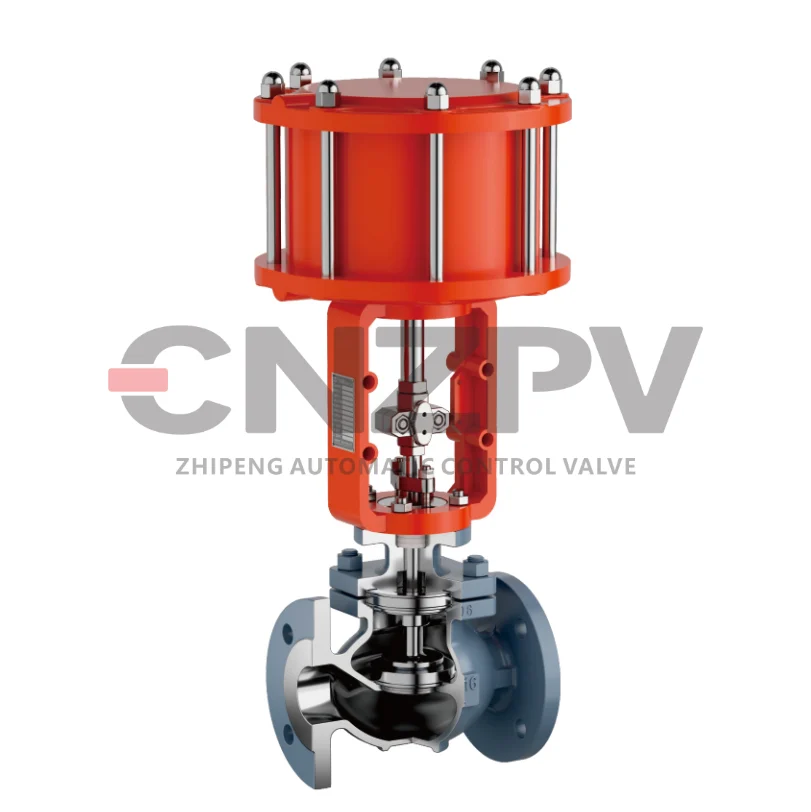

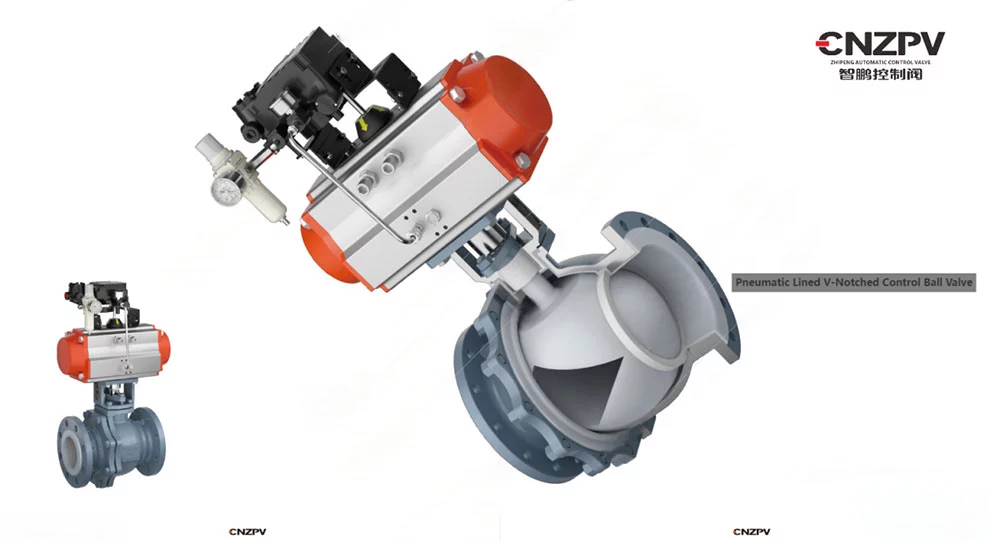

In industrial fluid control systems where precise regulation, corrosion resistance, and long-term reliability are critical, Lined V-Notched Control Ball Valves offer a superior solution. Unlike standard ball valves, these specialized valves feature a V-shaped notch in the ball and advanced fluoropolymer lining, making them ideal for throttling, modulating flow, and handling aggressive media.

This article explores the engineering advantages, key industrial applications, and operational benefits of lined V-notched ball valves, providing valuable insights for engineers, procurement specialists, and plant operators.

Technical Design & Functional Advantages

1. Precision Flow Control with V-Notch Design

Linear Flow Characteristics –The V-notch profile allows for proportional flow control, unlike standard ball valves that are primarily on/off devices.

Improved Turndown Ratio – Enables fine adjustments at low flow rates, essential for dosing and process control applications.

Reduced Cavitation & Flashing – The tapered design minimizes high-velocity flow issues common in throttling applications.

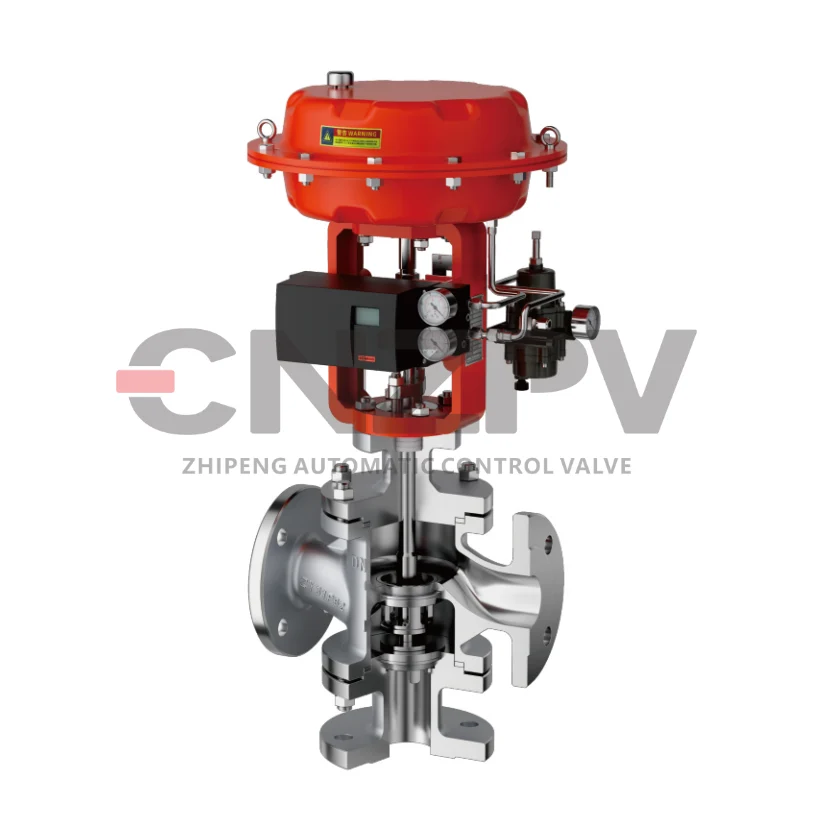

2. Corrosion & Chemical Resistance

Fluoropolymer Lining (PTFE, PFA, or ETFE) – Provides excellent resistance to acids, alkalis, solvents, and abrasive fluids.

Wide Chemical Compatibility – Suitable for sulfuric acid, hydrochloric acid, chlorine, and other aggressive media.

Metal-Free Wetted Parts – Prevents galvanic corrosion in electrochemical processes.

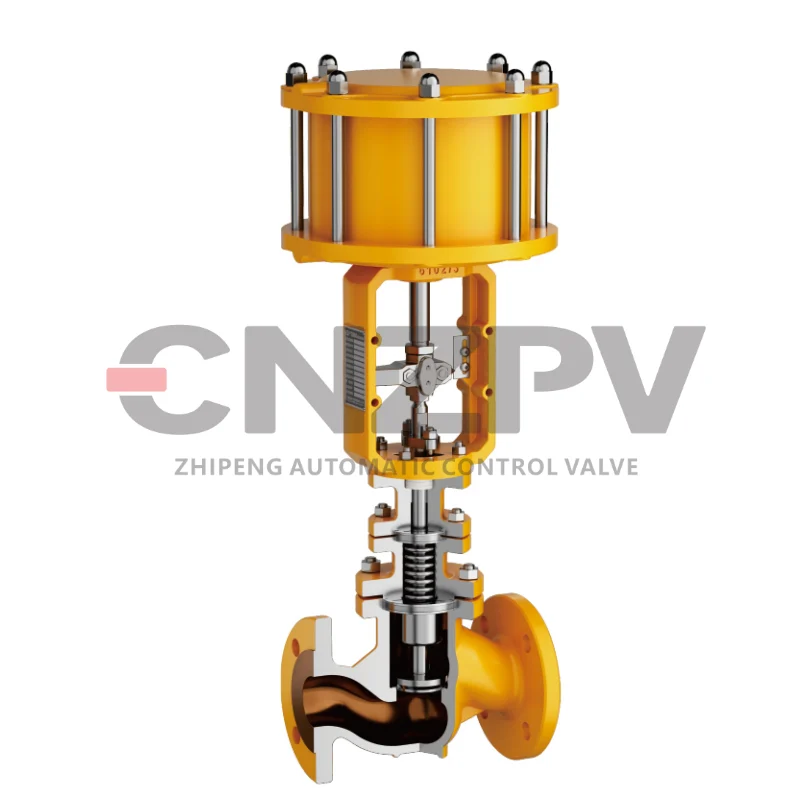

3. Robust Construction & Sealing Performance

Bubble-Tight Shutoff – Spring-loaded seats ensure zero leakage, even after prolonged use.

Fire-Safe & Anti-Static Options – Compliant with API 607/API 6FA for hazardous environments.

Low Torque Operation – Reduces actuator sizing requirements, lowering energy consumption.

Key Industrial Applications

1. Chemical & Petrochemical Processing

Acid & Caustic Handling – Resistant to H₂SO₄, HCl, NaOH, and organic solvents.

High-Purity Chemical Transfer – Prevents contamination in pharmaceutical intermediates and semiconductor-grade chemicals.

Polymer & Resin Production – Handles sticky, viscous fluids without clogging.

2. Water & Wastewater Treatment

Chlorine & Ozone Dosing – PTFE lining withstands aggressive disinfectants.

Slurry & Abrasive Media Control – PFA-lined valves resist erosion in mining and desalination plants.

3. Power Generation & FGD Systems

Flue Gas Desulfurization (FGD) – Handles limestone slurry and sulfuric acid mist.

Cooling Water & Boiler Feed Control – Reliable performance in high-temperature, high-pressure steam systems.

4. Oil & Gas (Upstream & Midstream)

Produced Water Treatment – Resistant to H₂S, CO₂, and brine solutions.

Chemical Injection Systems – Precise metering of corrosion inhibitors and scale preventers.

5. Food, Pharma & Biotechnology

Sanitary & CIP-Compatible Designs – Meets FDA, 3-A, and EHEDG standards.

Sterile Process Control – Used in fermentation, filtration, and clean utilities.

Why Choose Lined V-Notched Ball Valves Over Alternatives?

| Feature | V-Notched Ball Valve | Globe Valve | Butterfly Valve |

| Flow Control Precision | Good | Good | Poor |

| Chemical Resistance | PTFE/PFA Lined | Limited | Limited |

| Shutoff Class | ANSI Class VI (Bubble-Tight) | Class IV | Class III |

| Maintenance Needs | Low | High | Moderate |

| Lifetime Cost | Lower (Long Service Life) | Higher | Moderate |

Conclusion: Optimizing Process Efficiency with the Right Valve

Lined V-notched control ball valves provide unmatched precision, durability, and chemical resistance in demanding industrial applications. Their superior throttling capability, leak-proof performance, and low lifecycle costs make them a smart investment for engineers seeking reliable flow control solutions.

Need a custom-engineered valve solution? Contact CNZPV technical team today for expert guidance!